Promotion

Shop now and save 20% on your back-to-school purchases & get free shipping on orders $45+ Use code: SCHOOL24

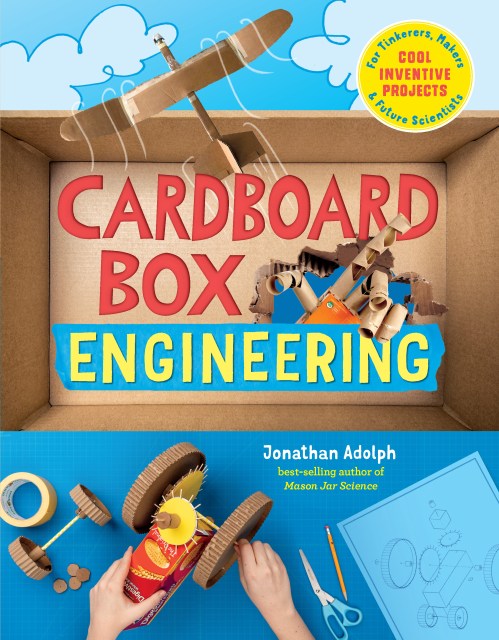

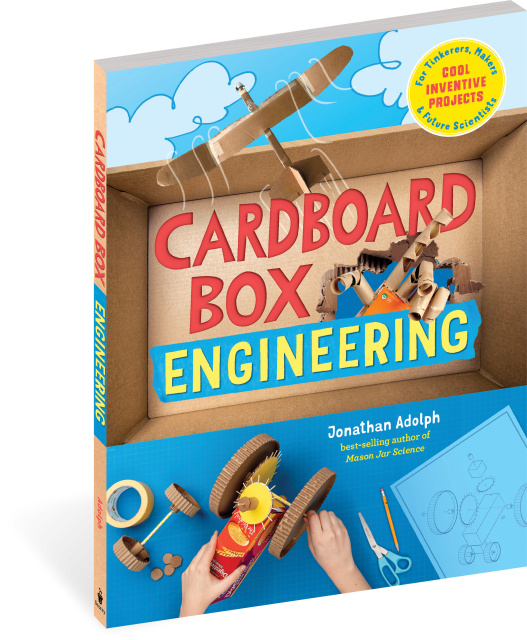

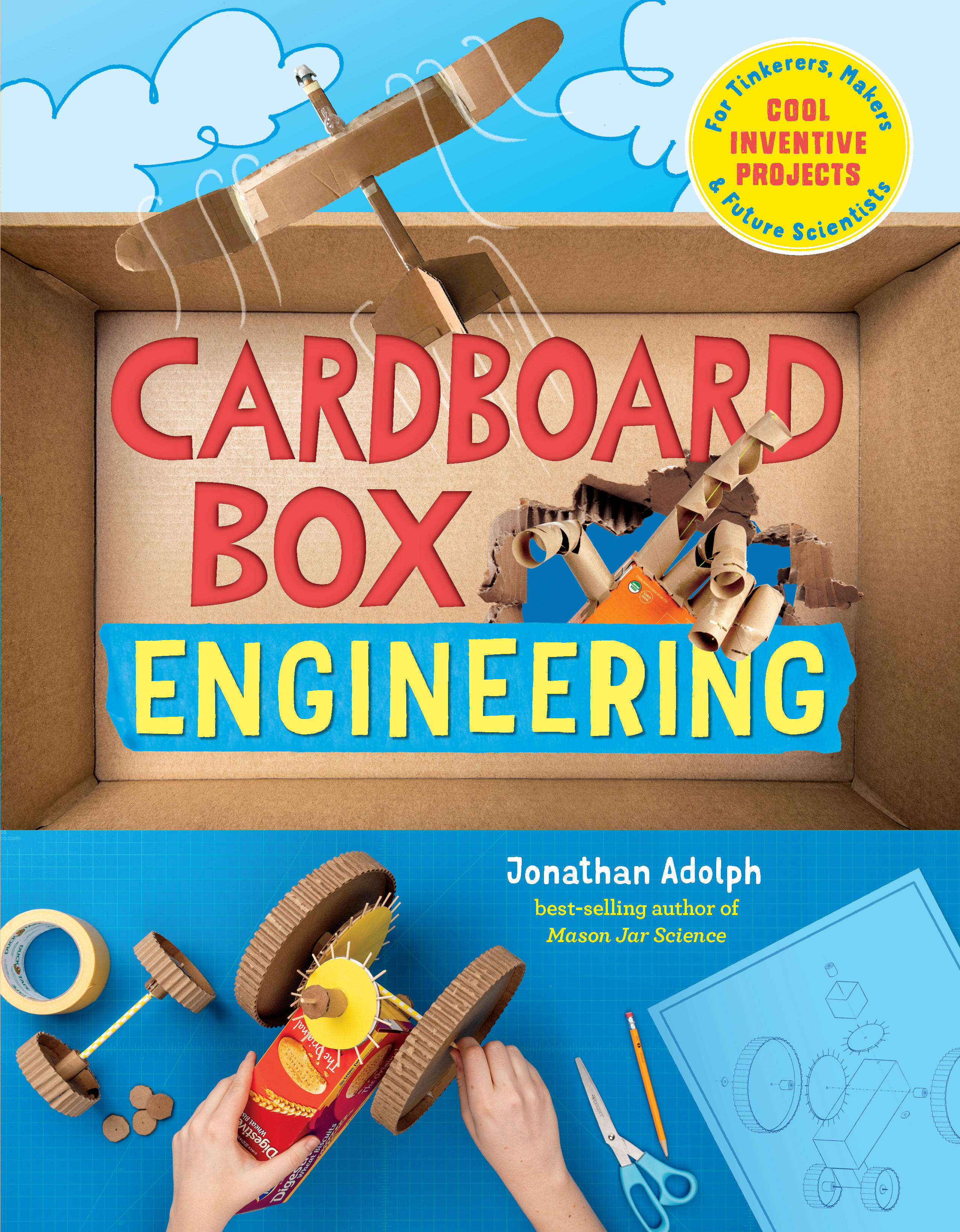

Cardboard Box Engineering

Cool, Inventive Projects for Tinkerers, Makers & Future Scientists

Contributors

Formats and Prices

Price

$16.99Price

$22.99 CADFormat

Format:

- Trade Paperback $16.99 $22.99 CAD

- ebook $11.99 $15.99 CAD

- Hardcover $26.99 $33.99 CAD

This item is a preorder. Your payment method will be charged immediately, and the product is expected to ship on or around October 27, 2020. This date is subject to change due to shipping delays beyond our control.

Also available from:

-

“I really wish I'd had a book like this when I was a kid, and I think any young person who gets their hands on this book is really lucky. Who knows what kind of awesomeness this will inspire? I can't think of a better way to get kids away from screens and working with their hands, thinking, and inventing. This book might even change the world!” — Christian Ristow, robotic sculpture artist

“STEAM activities, such as the ones featured throughout the text, foster creativity, problem-solving, and teach the value of repurposing items… An engaging addition to any “How To” section. This book could be an exciting resource for students and teachers.”

— School Library Journal

- On Sale

- Oct 27, 2020

- Page Count

- 176 pages

- Publisher

- Storey

- ISBN-13

- 9781635862140

Newsletter Signup

By clicking ‘Sign Up,’ I acknowledge that I have read and agree to Hachette Book Group’s Privacy Policy and Terms of Use